15311826613

Click to add WeChatThis year, Papua New Guinea revised its Mining Act, strictly limiting foreign investment in placer gold mining, allowing only domestic citizens to participate in the industry, while encouraging foreign investment through large-scale mining projects. This policy has once again fueled the placer gold boom. This article will focus on placer gold, introducing the beneficiation process!

The target ore in placer gold deposits is native gold, which typically exists in a free state. It is also frequently associated with heavy minerals such as ilmenite, zircon, and magnetite, as well as gangue minerals such as quartz, feldspar, and clay. However, due to the significant grain size differences between placer gold and other gangue minerals, gravity separation is usually used as the primary beneficiation method. The placer gold gravity separation process includes: washing, screening, gravity separation, refining, and recovery.

The main purpose of placer gold washing is to remove the clay coating on gold particles, preventing them from being lost with waste rock during subsequent sorting processes, thereby improving gold recovery rate. Commonly used washing equipment includes vibrating screens and cylindrical washing machines.

Vibrating Screen: Through high-frequency vibration, the ore is brought into full contact with the water flow, dispersing and washing away the clay;

Cylindrical Washing Machine: The ore is propelled forward by spiral blades on the inner wall of the cylinder, while water flow is used to wash it, achieving separation of clay and ore.

In practical applications, for placer gold deposits with high clay content, a multi-stage washing process is often used to ensure washing effectiveness.

The main purpose of placer gold screening is to remove large pieces of waste rock, making the particle size of the material entering subsequent sorting processes more uniform. The screen aperture size is usually set at 10-20mm, which effectively removes large pieces of waste rock while ensuring that gold particles are not over-screened. The commonly used equipment is mainly a cylindrical screen, which uses rotation to circulate and screen the material inside the cylinder, separating the material that meets the particle size requirements for the next stage.

In high-grade mining areas, some companies use double-layer screens (an upper 20mm coarse screen and a lower 10mm fine screen) to achieve accurate particle size classification.

Jig gold concentration: Suitable for processing coarse-grained placer gold >3mm. It achieves mineral stratification through vertical pulsating water flow. The rising water flow loosens and suspends the mineral particles, allowing the lighter gangue to rise quickly; during the descending water flow, the mineral particles settle tightly, and the gold particles rapidly sink to the bottom and are discharged through the outlet. By adjusting parameters such as the jig's stroke, frequency, and water flow velocity, gold particles can be effectively separated from other minerals.

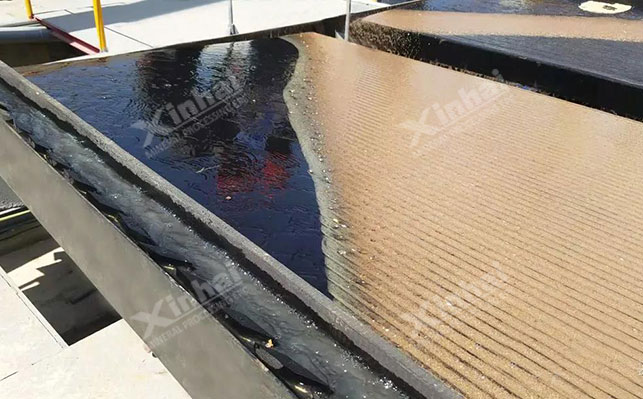

Shaking table gold separation: This method is effective for enriching gold particles of 0.019-3mm, but has a relatively small processing capacity. Utilizing the shaking table's surface structure and differential motion, mineral particles are separated on the table surface according to density and particle size. Gold particles move towards the concentrate end, while gangue is discharged towards the tailings end. By adjusting parameters such as table slope, stroke, stroke frequency, and lateral water flow velocity, the separation effect can be optimized, achieving effective recovery of fine-grained gold.

Sluice box gold separation: This method is suitable for fine-grained placer gold of 0.1-0.37mm, with a large processing capacity but a relatively low recovery rate.

Gold sluices utilize the difference in flow velocity of mineral particles on an inclined sluice surface for separation. Heavier gold particles settle faster and deposit at the bottom of the sluice, while lighter particles are discharged with the water flow. In some small-scale placer gold mining, sluices are often used to rapidly enrich placer gold and obtain preliminary rough concentrate.

Centrifuge Gold Separation: Its main purpose is to enhance the settling of fine gold particles. Through the centrifugal force generated by high-speed rotation, gold particles adhere to the drum wall and are discharged as concentrate after being rinsed with water. Centrifuges are highly automated, have good recovery effects on fine gold particles, and are equipped with an automatic discharge system that adjusts the discharge time in real time according to the concentrate concentration, reducing manual intervention.

Amalgamation: This method utilizes the wettability of mercury on gold to form an amalgam, thus enriching gold. On an amalgamation plate (mercury-plated copper plate), gold and mercury come into contact as the ore slurry flows, forming an amalgam. Subsequently, mercury and gold are separated by distillation (at 356℃). However, this method causes severe mercury pollution and has been gradually replaced by technologies such as carbonaceous adsorption materials and resin extraction.

Magnetic Separation and Electrostatic Separation: The aim is to recover associated minerals in placer gold deposits. Magnetic separation mainly targets associated minerals such as magnetite and ilmenite, using high-gradient magnetic separators to enrich magnetic minerals. Electrostatic separation is based on the differences in mineral conductivity, using a high-voltage electric field to recover non-magnetic heavy minerals such as rutile and zircon.

The above is an introduction to the principle and process of gravity separation for placer gold. Due to its density variations, placer gold is often primarily separated by gravity. However, depending on different mineralization conditions and ore properties, other techniques such as flotation cyanide extraction are also used. In actual concentrators, the selection of a placer gold beneficiation process requires comprehensive consideration of the specific circumstances.

Xinhai has extensive experience in gold ore beneficiation. Whether it's a rock gold mine or a placer gold mine, we can professionally customize and design suitable process solutions to ensure effective recovery and a high return on investment.