15311826613

Click to add WeChatIn the gold mining industry, finding low-cost, high-efficiency gold extraction processes has always been a key driver of industry development. With the gradual depletion of high-grade gold ore reserves, the development and utilization of low-grade gold ore (typically referring to gold grades in the range of 0.5~3 g/t), as well as tailings and waste rock, has indeed become a focus of industry attention. Heap leaching gold extraction, with its low cost and high efficiency, provides a feasible path for the effective utilization of low-grade gold ore. Let's explore heap leaching gold extraction technology and the secrets to its low cost and high efficiency.

Heap leaching gold extraction is a process specifically designed for extracting gold from low-grade gold ores. The process involves stacking ore crushed to a certain particle size into a heap of a certain size. Then, a cyanide solution is sprayed onto the ore, utilizing the chemical reaction between the solution and the gold in the ore to dissolve the gold in the solution, forming a gold-bearing precious solution. Gold is then recovered from the precious solution using methods such as activated carbon adsorption or zinc powder replacement. The process mainly includes the following steps:

Crushing: Large mined ore blocks are fed into a crusher for crushing, reducing the particle size to approximately -50mm. Then, excessively large or small particles are removed by screening.

Heap Construction: In a site treated with anti-seepage measures, crushed and screened ore is piled up at a certain height and slope. An anti-seepage pad is usually laid at the bottom of the heap to prevent the leachate from leaking and polluting the soil and groundwater. Furthermore, the heap leaching pad must be designed for permeability and stability to ensure uniform distribution and flow of the solution.

Spraying: A spray system installed on top of the heap evenly sprays the prepared leachate (sodium cyanide) onto the surface of the ore heap. The solution gradually penetrates the ore heap, reacting with the gold in the ore, dissolving the gold to form a soluble complex, and then flowing along the collection channel at the bottom of the heap into a storage tank.

Leaching: The entire leaching process takes an indefinite amount of time, depending on the ore type, gold content, and leaching conditions configured in the process. The gold concentration in the leachate needs to be monitored periodically to assess recovery efficiency.

Precious Solution Recovery: The precious solution containing dissolved gold is collected from the bottom of the ore heap and transported through pipelines to subsequent processing steps.

Gold Extraction: Gold can be enriched by adsorbing it onto activated carbon using a dynamic countercurrent adsorption column; alternatively, zinc powder can be added to the gold solution to react with gold cyanide complexes, forming a solid gold precipitate, which is then desorbed and electrolyzed.

Electrowinning: Gold in the desorbed solution is deposited onto a cathode plate to form a high-purity gold mud, which is then smelted to obtain the finished gold product.

The key to achieving low-cost operation in heap leaching gold extraction technology lies in the accurate control of process design towards "simplifying steps, reducing consumption, and minimizing input.

Simple process and low equipment cost:

Heap leaching gold extraction overturns the high-energy-consuming process of "fine grinding + complex separation" in traditional gold beneficiation. It only requires coarsely crushing the raw ore to -50mm (some can even retain it to -100mm), and then feeding in reagents. This eliminates the overall energy consumption and input costs of grinding; and there is no need to build a large-scale beneficiation plant, only requiring the laying of an impermeable layer, the construction of a spray system and a precious liquor recovery pool in an open-air site, greatly reducing infrastructure costs.

Low material consumption and controllable costs: In the heap leaching gold extraction process, the leachate can be recycled. For low-grade gold ores, the amount of cyanide required is only 0.2-0.5 kg/t, far lower than the 1.0-1.5 kg/t required for stirred leaching. Furthermore, low-grade ores contain fewer impurities, eliminating the need for additional reagent consumption for impurity removal reactions. In addition, the lifespan of materials such as geomembranes and spray pipes required for heap leaching can reach 5-10 years, resulting in low annual amortized costs.

Simple maintenance and low labor costs: Heap leaching equipment mainly consists of pipes, pumps, and spray heads, making maintenance relatively simple. Moreover, the spray system in heap leaching can be fully automatically controlled through timers and level sensors, significantly reducing labor costs.

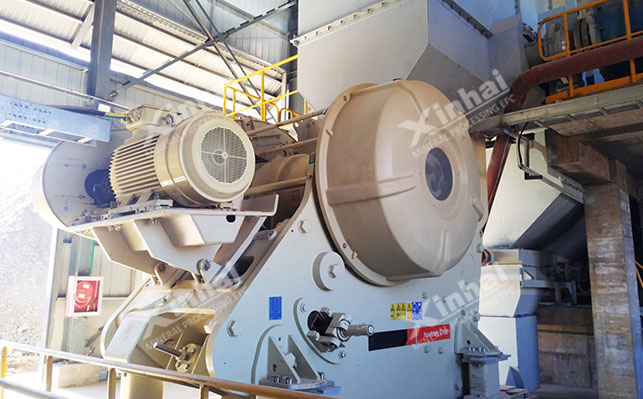

The Mongolia 5500TPD gold mine beneficiation project is a full-chain mining service project undertaken by Xinhai Mining Equipment. Entrusted by the client, we completed the beneficiation plant design and gold smelting construction engineering design for this project.

After receiving approximately 500 kg of primary ore samples, Xinhai Mining Equipment conducted experimental analysis. Based on the local beneficiation plant's terrain survey, experimental reports, and considering investment and environmental factors, we designed a crushing, heap leaching, desorption electrolysis, and smelting process.

For low-grade oxide ores, heap leaching was used to recover gold; while for high-grade oxide ores, whole-sludge cyanidation leaching was used. This effectively reduced investment costs while ensuring a high gold recovery rate.

For this design project, Xinhai Mining Equipment's Mine Design Institute established a dedicated project team, delivering a complete beneficiation plant design in just three months. The client was impressed by Xinhai Mining Equipment's technical strength and service attitude, and subsequently decided to pursue deeper cooperation with them.