15311826613

Click to add WeChatPolymetallic rich iron ore is a kind of mineral resource with complex composition. Besides the main iron ore, it often contains a variety of metal minerals, including copper, zinc, lead, silver, rare earths, cobalt and nickel ores, etc. This type of iron ore is closely associated with other minerals and is a difficult-to-select type of iron ore. In addition, apart from iron which can be enriched, other valuable metals also have enrichment value. Therefore, this article will focus on introducing of the metal iron ore beneficiation process to see how it recovers iron and other metal minerals.

The beneficiation process of polymetallic rich iron ore is designed based on the core idea of "prioritizing iron beneficiation and then successively recovering manganese, lead and silver", which can fully utilize the differences in the physical and chemical properties of each mineral to achieve efficient separation and recovery of resources.

After the raw ore is crushed and roughly ground, it is first subjected to gravity separation or magnetic separation for coarse-grained pre-selection, which can effectively remove a large amount of gangue minerals and reduce the processing volume of subsequent grinding and separation. Gravity separation can be achieved by using a jigging machine or a heavy medium cyclone. The initial separation is realized by taking advantage of the density difference between iron minerals and gangling, and 30% to 50% of the tailings can be quickly discarded. Magnetic separation is carried out for the pre-selection of strongly magnetic minerals. A weak magnetic separator can capture strongly magnetic minerals such as magnetite, and the tailings throwing effect is relatively good.

The ore after coarse-grained pre-selection needs to be finely ground to ensure that the iron minerals are fully dissociated individually. Generally, the grinding fineness is controlled at -0.074mm, accounting for 70%-80%. The finely ground materials are subjected to a combined process of strong magnetic separation and reverse flotation to extract iron concentrate. Strong magnetic separation uses a high-gradient magnetic separator. Through the high-gradient magnetic field generated by the magnetic concentrating medium, weakly magnetic iron minerals are adsorbed onto the surface of the medium to achieve separation, which can effectively recover weakly magnetic minerals such as hematite and limonite. Reverse flotation is used for desilication treatment to further increase the grade of iron concentrate. Usually, starch is used to suppress iron minerals, and fatty acid collectors are used to flotation silica and other siliceous Ganges, which can increase the grade of iron concentrate to over 60%.

In the tailings produced after careful selection, there are still some residual iron minerals, especially those with weak magnetism or fine-grained interlocking. Therefore, iron re-selection and recovery of this tailings are required, and the process of magnetic roasting - weak magnetic separation is usually adopted. Tailings are heated to 600-800℃ in a reducing atmosphere to reduce the weakly magnetic hematite and limonite to the strongly magnetic magnetite. Then, they are recovered through a weak magnetic separator, reducing the iron grade in the tailings from 10% to below 5% and increasing the total iron recovery rate by 15%-20%.

Generally, manganese minerals mainly exist in two forms: independent manganese minerals (such as rhodochrosite and pyrolusite) and iron-manganese co-occurring minerals (such as manganese hematite and manganese limonite). The physical and chemical properties of independent manganese minerals are quite different from those of other minerals and are relatively easy to separate. However, due to the similar properties of iron-manganese co-occurring minerals to iron minerals, the separation of iron-manganese co-occurring minerals is relatively difficult, and the process needs to be selected specifically.

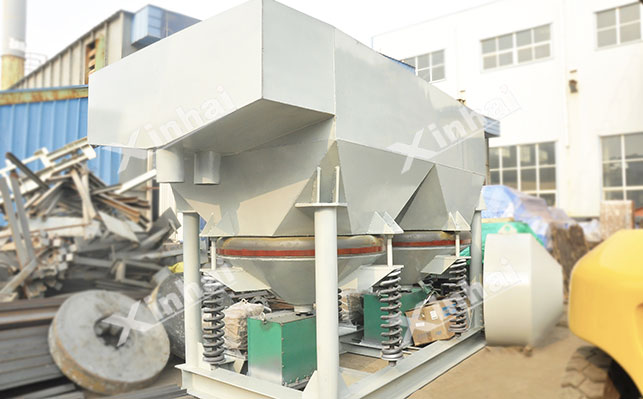

For coarse-grained embedded manganese minerals (with a particle size greater than 0.074mm), gravity separation can be adopted. In this method, the shaker and the spiral chute utilize the density difference of minerals to achieve separation. Through the combined effect of asymmetric reciprocating motion and lateral water flow of the shaker, the manganese minerals with higher density move towards the concentrate end, while the ganglion minerals with lower density flow towards the tailings end. The spiral chute relies on the flow of pulp within the spiral chute and the effect of centrifugal force to enrich manganese minerals at the inner edge of the chute, thereby obtaining manganese crude concentrate with a relatively high grade.

The specific magnetic susceptibility of manganese minerals is different from that of iron minerals. The medium and strong magnetic separator can be used to further separate manganese minerals from iron minerals. Under an appropriate magnetic field intensity (typically 8000-12000Gs), manganese minerals are adsorbed on the magnetic poles of the magnetic separator, while iron minerals or gangvein minerals are discharged with the pulp, achieving the initial enrichment of manganese.

For fine-grained interwoven manganese minerals (with a particle size less than 0.02mm), the flotation process is more effective. Anionic collectors (oleic acid, sodium oleate) are used. In a weakly alkaline pulp environment (pH=8-9), the carboxyl groups of the collectors undergo chemical reactions with the metal ions on the surface of manganese minerals to form hydrophobic complexes, causing the manganese minerals to float up. To enhance selectivity, combined collectors are often added and combined with inhibitors such as sodium silicate to suppress gangue minerals, which can yield concentrates with a manganese grade of over 30%.

Lead and silver minerals are mainly carried by galena, and flotation is a key process for recovering lead and silver. Before flotation, the pulp needs to be activated. Usually, copper sulfate is added as an activator to enhance the adsorption capacity of galena surface for collectors.

The priority flotation adopts the strategy of "suppressing iron and manganese and floating lead and silver". Starch is used to suppress iron minerals, and sodium silicate is used to suppress manganese minerals and gangue. Xanthate (such as butyl xanthate) and black xanthate (such as ethylthiazone) collectors are selected to flotation lead and silver minerals, and lead and silver concentrates with a lead grade of over 45% and a silver content of over 1000g/t can be obtained. If lead and silver minerals are closely coexisting and difficult to achieve effective separation, a mixed flotation process is adopted. First, a Pb-Ag mixed concentrate is obtained. Then, it is dedosed with cyanide (such as sodium cyanide) or sodium sulfide. Subsequently, galena is inhibited by the sulfite method or the dichromate method, and silver minerals are separated by flotation to achieve efficient separation of lead and silver.

When silver exists in the form of independent minerals (such as pyroxene and ceratinite) and is not effectively enriched during the flotation process, it can be recovered by cyanidation leaching or thiourea method. Cyanide leaching is carried out under alkaline conditions (pH=10-11), where cyanide forms a stable complex with silver ions to leach silver from the ore. Then, silver is recovered through zinc powder displacement or activated carbon adsorption. The thiourea method uses acidic thiourea solution as the leaching agent. In the presence of an oxidant, silver is dissolved to form a complex, which is mostly suitable for treating complex silver oxide ores.

The above is an introduction to the design of the beneficiation process for a certain polymetallic rich iron ore based on the principle of "prioritizing iron beneficiation, followed by the sequential recovery of manganese, lead and silver" according to the nature of the ore. In actual beneficiation plants, for the beneficiation of polymetallic rich iron ore, it is necessary to first understand the mineral properties and strive to achieve the comprehensive recovery of useful minerals as much as possible to improve the utilization rate of minerals.

Xinhai has extensive experience in the beneficiation of polymetallic ores and has participated in numerous beneficiation projects. For instance, in the 5,000t /d silver polymetallic ore beneficiation project of Inner Mongolia Zhuhe completed by Xinhai, through experimental analysis, a two-stage continuous grinding - flotation - comprehensive concentrate regrinding - secondary leaching and secondary washing - zinc powder replacement process flow was tailor-made for it. Eventually, The total recovery rate of Ag beneficiation for ore supply in Zone II was 80.15%. The total recovery rate of Au beneficiation was 90.32%.